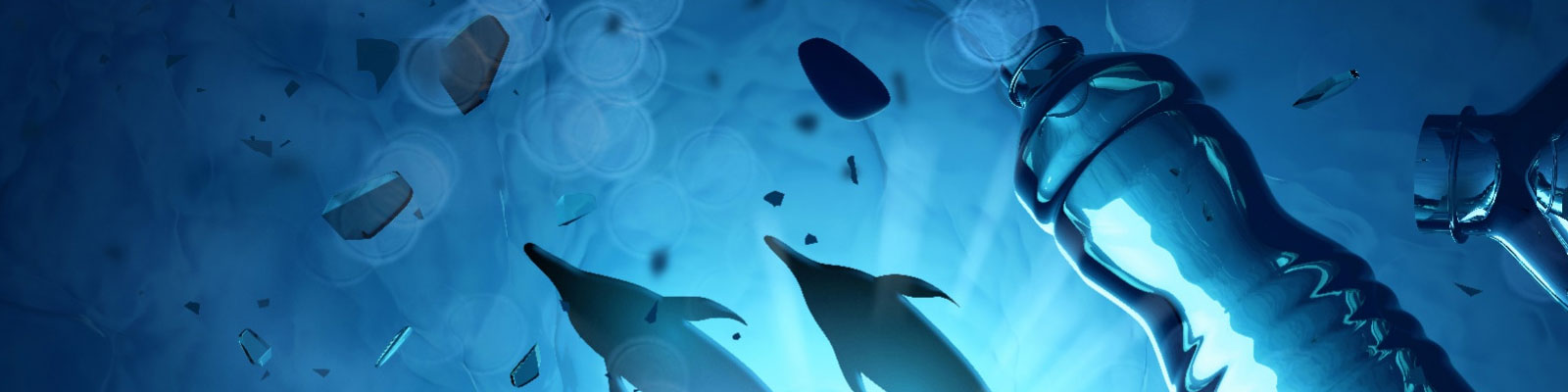

A RPET fabric is an environmentally friendly fabric blend. RPET stands for Recycled Polyethylene Terephthalate, in other words, recycled PET or RPET. RPET cloth is made from recycled plastic bottles and cotton or other synthetic or natural fibers. RPET fabric blends have different blending ratios, 50/50, 60/40, 70/30, etc. Some Facts about plastic wastes and RPET textile products: 51 billion plastic bottles go to the landfills each year. It will take 700 years before plastic bottles in landfills start to decompose Recycling 1 ton of RPET containers saves 7.4 cubic yards of landfill space RPET fabrics have a 50% lower carbon footprint than organic cotton. When buying RPET clothing, you can be rest assured that it is a recycled material. Plastics bottles that are recycled would have ended up sitting in a landfill somewhere if it weren’t for this process or turning it into a fabric. The ease of mind of providing clothing to customers that is recycled is something we take great pride in and you will too!

Benefit when using RPET fabrics?

Using recycled fabrics can help reduce waste and conserve resources. By repurposing materials that would otherwise end up in landfills or oceans, recycled fabrics help divert waste from the environment and reduce the need for new materials. In addition, producing recycled fabrics can use less energy and water than producing new fabrics, which can help reduce carbon emissions and water usage.

Durable

Recycled fabrics can be just as durable as traditional fabrics, depending on the type of material and the manufacturing process. Some recycled fabrics, such as those made from recycled polyester, can be just as strong and long-lasting as virgin polyester. However, it’s important to care for recycled fabrics properly to ensure their longevity.

How are recycled fabrics are made?

Recycled fabrics are made by taking discarded materials and processing them into new fibers. The process can vary depending on the type of material being recycled, but generally involves cleaning, shredding, and melting the materials down to create new fibers. These fibers can then be spun into yarns and used to make new textiles.

What is GRS?

GRS is the abbreviation of Global Recycled Stand. GRS is a voluntary product standard for tracking and verifying the content of recycled materials in a final product. The standard applies to the full supply chain and addresses traceability, environmental principles, social requirements, chemical content and labeling. The GRS covers processing, manufacturing, packaging, labeling, trading and distribution of all products made with a minimum of 20% recycled material. It also sets requirements for third-party certification of recycled content, chain of custody, social and environmental practices, and chemical restrictions.